Product Categories

- SMS 16000MT Aluminum extrusion line for sale

- 5500mt aluminum extrusion press

- 2700MT aluminum extrusion press

- 2200MT Aluminum extrusion press

- 1800MT aluminum extrusion press

- 1400MT Aluminum extrusion press

- 750MT aluminum extrusion press

- 1100MT Aluminum extrusion press

- 650MT Aluminum extrusion press

- General aluminum extrusion presses technical specifications

- die casting machine for sale

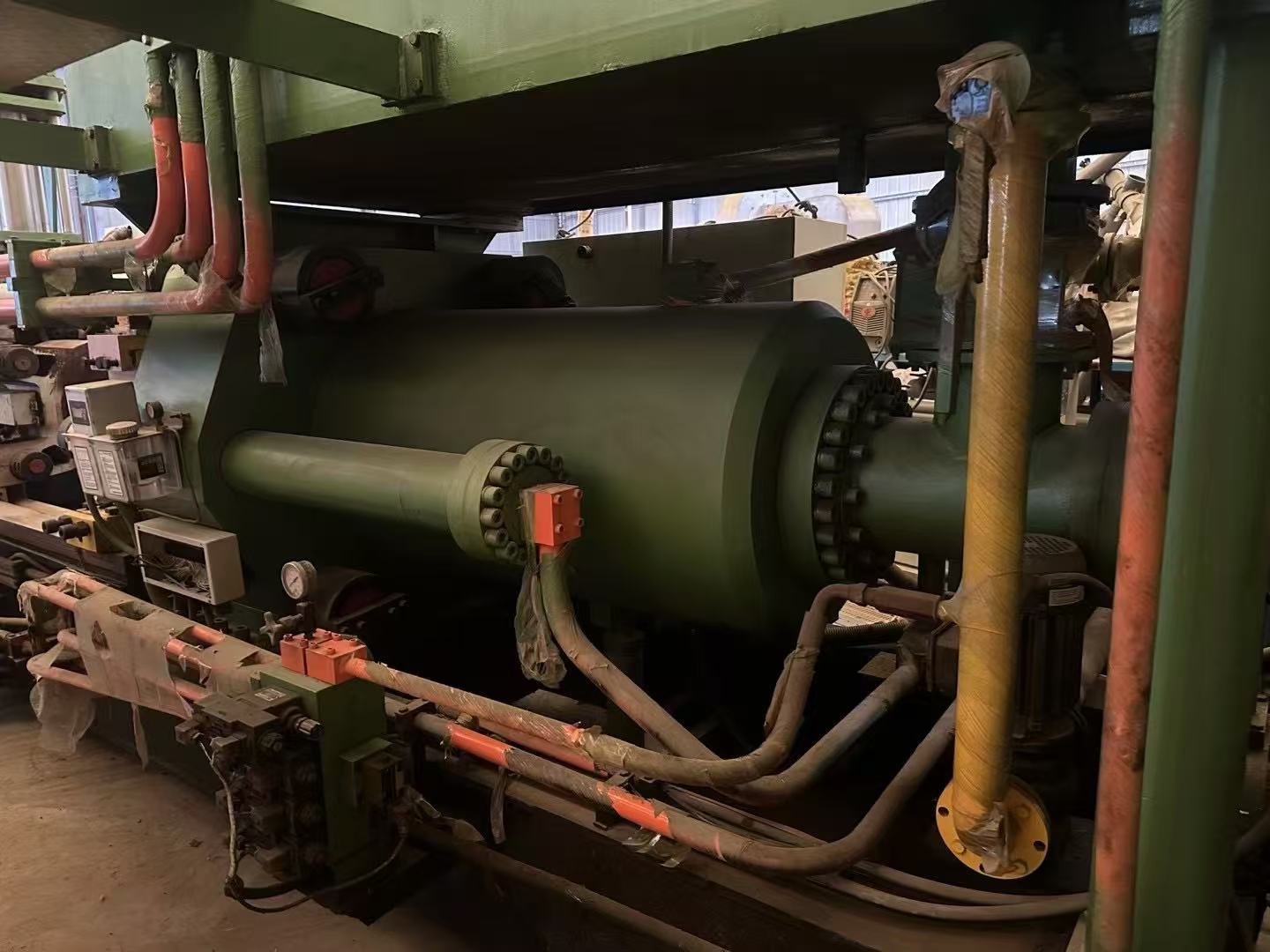

Extrusion capacity: 650MT

Year 2014

Direction:right

Origin: Made in China

Supply:only press

used 650MT aluminum extrusion press Technical Parameters:

(1) Billet size

|

Billet size: |

Ф90mm(3.5 inch), maximum length 480mm。 |

(2) Extrusion capacity

|

Diameter of main cylinder piston: |

580mm |

|

Diameter of side cylinder piston: |

140mm*2 pieces |

|

Diameter of container cylinder: |

130mm*4 pieces |

|

Diameter of shear cylinder: |

130mm |

|

Total extrusion strength: |

220kg/cm2 659 MT |

|

Main cylinder extrusion: |

220kg/cm2 581 MT |

|

Side cylinder extrusion: |

220kg/cm2 78 MT |

|

Container lock-up: |

200/kg /cm2 108 MT |

|

Shear: |

160/kg/ cm2 20 MT |

(3) Stroke

|

Stem: |

1140 mm |

|

Container : |

350 mm |

|

Shear: |

350 mm |

(4) Speed

|

Main ram fast forward: |

310 mm/s |

|

Main ram fast backward : |

200mm/s |

|

Container lockup: |

250mm/s |

|

Container open: |

250mm/s |

|

Shear down: |

350mm/s |

|

Shear up: |

400mm/s |

(5) Theory speed

|

Extrusion speed: |

0.2~9.5mm/sec |

|

Dead cycle is less than 20 seconds,not including upsetting or burp cycle. |

|

(6) Die stack size, auto die cassette:

|

diameter ф200mm |

length:240mm |

2. Specification

(1) Oil pump

|

Main oil pump: |

A7VSO170E (LIHAO,made in China)*1 set |

|

Auxiliary pump: |

SQP35-38(Tokimec, made in Japan)*1set |

(2) Hydraulic parts:

High pressure hydraulic valves are from Rexroth.Low pressure valves are from Taiwan Jeou Gang.

(3) Motor:

|

Main motor: |

YE2M-280M1-6-65kW *1set(made in China) |

|

Total Install power |

85kW |

|

Heat exchanger capacity |

6 m2 |

(4) Die stack :Dia200*Length 200mm; Front platen hole : Dia110* Oval 130mm

(5) machine overalldimension : 5910mm (L)*2650mm (W)*2920mm (H)

(6)Material:

|

Main cylinder: |

35# forged steel |

|

Main piston: |

chilled casting iron (HRC:48-50º) |

|

Front platen: |

45# casting steel (300mm) |

|

Die stack: |

45# forged steel |

|

Cross head: |

45# forged steel |

|

Tie rod: |

42crmo steel (¢160mm) |

|

Container housing: |

Q345 steel structure |

|

Container tire: |

5crmnmo |

|

Container liner: |

H13 forged steel |

|

Stem: |

H13 forged steel |

|

Dummy block: |

H13 forged steel |

|

Bottom shelf: |

35# H steel and steel plate welding |

(5) Electrical Components:

PLC: Mitsubishi FX3U-80MR

Constant speed and segment speed control switch can be realized

Contactor:Made in China

Stroke switch:Made in China

Photoelectric switch: Made in China

Relay:Made in Japan, protects PLC output

Control panel: hanging type